dual shaft low speed worm dc gear motor for mixers

Features:

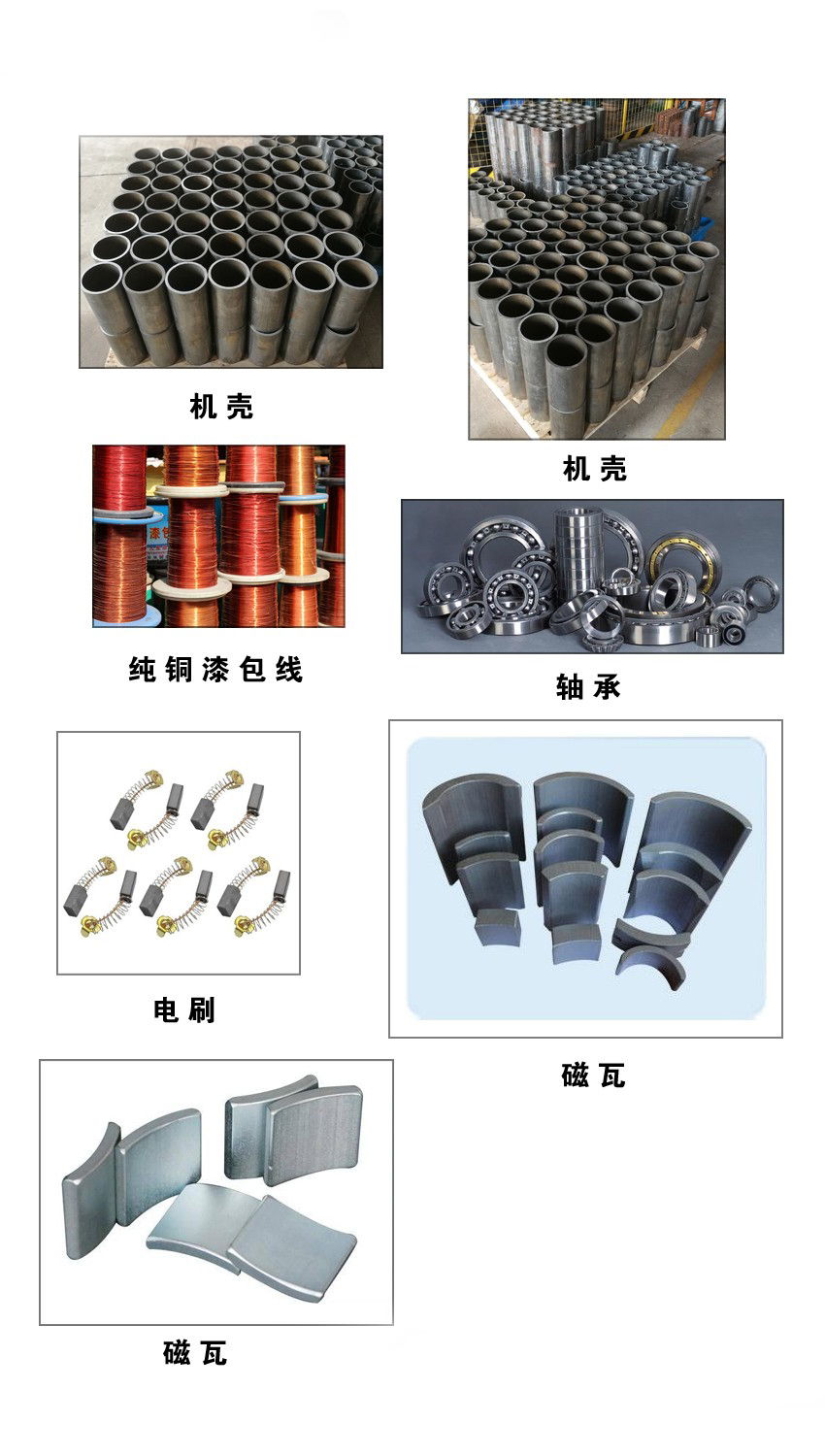

1. Motor type: Brushed DC motor

2 .Gearbox: Worm gearbox, planetary reducer

3. Voltage: 24v- 220v

4. Speed:20rpm-500rpm

5. Type: 70ZYT, 80ZYT, 90ZYT, 110ZYT

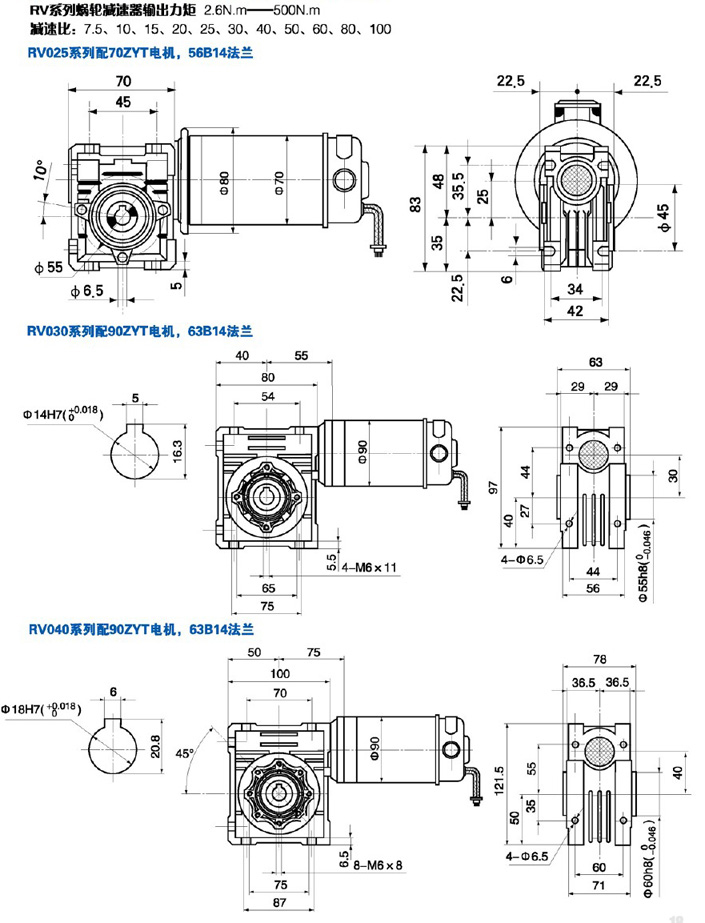

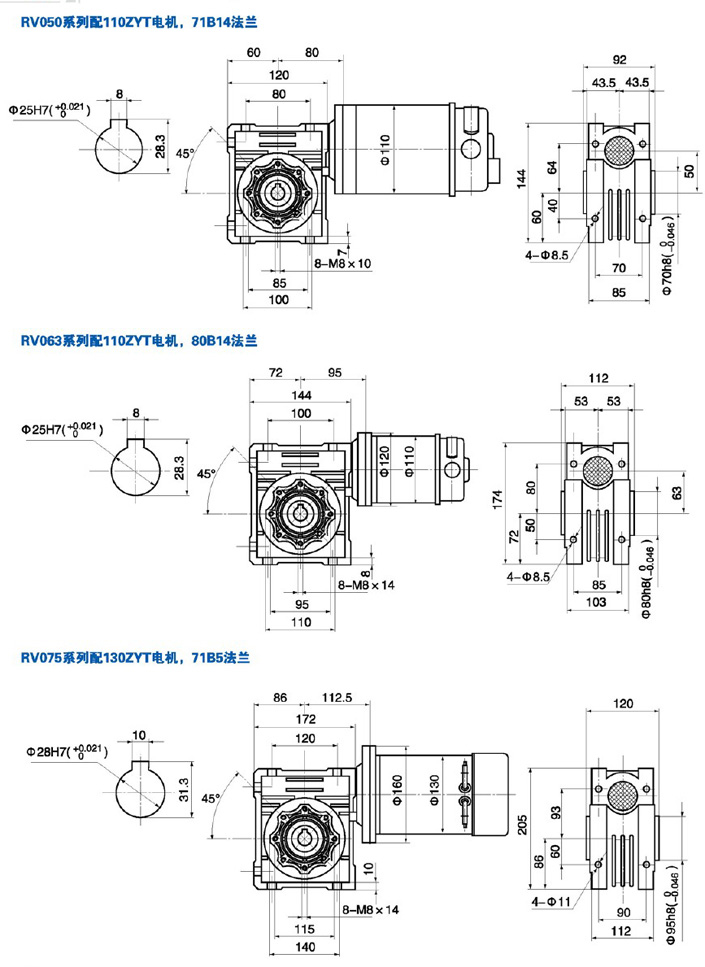

6. Worm gear box: RV030, RV040, RV050, RV063, RV075, NMRVgear reducer

7. Typical application: Brushed motors are widely used in various industrial and commercial applications due to their simple design, low cost, and ease of maintenance. They are suitable for applications that require low to medium power output and low to medium speed operation.

- Information

- Video

- Downloads

The DC dual shaft worm gear motor is a fixed-speed reduction motor, where once the speed ratio and motor are selected, the output speed remains constant. However, in practical applications, there are often requirements for variable speeds, such as the spindle speed of a lathe, the stirring shaft speed of various mixers, or the conveyor speed for different materials. How to achieve speed control is a topic of great concern for engineering professionals. Below, we will briefly describe various speed control methods commonly used in engineering:

Multi-step speed control and variable-pole speed control are the simplest and most economical methods. However, they are limited to small and medium capacities (up to 2kW) and applications with a low number of starts. Typically, only two speed options are available, with a relatively small speed control ratio (1:2 to 1:6) and a maximum of three speed options. In specific industries such as lathes, multi-step speed control is often achieved using gearboxes with multiple gears. Although multiple speed options are available, the speed control range is limited.

Stepless speed control can be divided into mechanical and electrical methods. The common mechanical method involves incorporating a mechanical stepless speed control device (such as belt pulley or friction disc) at the coupling between the motor and the gearbox. Its advantages include smooth speed control, simple structure, and suitability for harsh environments. However, its disadvantages are limited speed control range (generally within 1:10) and the belt or friction disc being consumable parts that require regular maintenance and replacement. The electrical method involves series speed control of asynchronous motors, rotor resistance speed control, or voltage control speed control for DC motors.

In summary, the DC dual shaft worm gear motor provides a reliable and efficient solution for applications where variable speed control is required. By considering the specific needs of the application, engineers can choose the most suitable speed control method to achieve the desired performance and functionality.

This series of motors operates smoothly with low noise, high transmission speed ratio, and strong carrying capacity. They can be matched with various types of motors to achieve speed regulation and drive control.

We make Customizable voltage, dimension, performance, shaft, mounting...etc

We make integrated encoder, gearbox, brake...etc

Please Send Inquiry or Question, and We will get you the Best and Most Cost Effective Solution/Proposal.

OPTIONS:

Size: 32mm 36mm 38mm 42mm 52mm 57mm 60mm 63mm 70mm 76mm 80mm 90mm 110mm

Rated voltage : 10v 12v 18v 24v 36v 48v upto 380vdc

Rated torque : upto 3Nm (calculated without gearbox)

Rated speed: upto 15000rpm

Rated power: upto 1000w

Protection class IP 40 50 54 56 66 67 Option

BELOW ARE ONLY TYPICAL MODELS, PLS CONTACT US FOR CUSTOMIZED MOTORS

These are standard shafts of our company above. The diameter of the output shaft can be 6mm, 8mm, 10mm, 12mm, 14mm and so on.We can design and manufacture the shafts according to your demand.

The parameters of the motor above are for your reference.We can design and manufacture according to your required like voltage, power,speed,torque and dimensions.

| Type | Torque | Speed | Power | Voltage | Current(A) | CW/CCW |

| (mN.m) | (r/min) | (w) | (v) | < | speed tolerance(r/min) | |

| 110ZYT01 | 784 | 1500 | 123 | 110 | 1.8 | 100 |

| 110ZYT02 | 784 | 1500 | 123 | 220 | 0.9 | 100 |

| 110ZYT03 | 637 | 3000 | 200 | 110 | 2.8 | 200 |

| 110ZYT04 | 637 | 3000 | 200 | 220 | 1.4 | 200 |

| 110ZYT05 | 637 | 3000 | 200 | 24 | 13 | 200 |

| 110ZYT51 | 1177 | 1500 | 185 | 110 | 2.5 | 100 |

| 110ZYT52 | 1177 | 1500 | 185 | 220 | 1.25 | 100 |

| 110ZYT53 | 980 | 3000 | 308 | 110 | 4 | 200 |

| 110ZYT54 | 980 | 3000 | 308 | 220 | 2 | 200 |

| 110ZYT55 | 980 | 3000 | 308 | 24 | 16.5 | 200 |

| Type | Torque | Speed | Power | Voltage | Current(A) | CW/CCW |

| (mN.m) | (r/min) | (w) | (v) | < | speed tolerance(r/min) | |

| 110ZYT101 | 1560 | 1500 | 245 | 110 | 3 | 100 |

| 110ZYT102 | 1560 | 1500 | 245 | 220 | 1.5 | 100 |

| 110ZYT103 | 1274 | 3000 | 400 | 110 | 4.8 | 200 |

| 110ZYT104 | 1274 | 3000 | 400 | 220 | 2.4 | 200 |

| 110ZYT105 | 1274 | 3000 | 400 | 24 | 22.5 | 200 |

| 110ZYT151 | 2390 | 1500 | 375 | 110 | 4.5 | 100 |

| 110ZYT152 | 2390 | 1500 | 375 | 220 | 2.3 | 100 |

| 110ZYT153 | 2230 | 3000 | 700 | 110 | 8.5 | 200 |

| 110ZYT154 | 2230 | 3000 | 700 | 220 | 4.2 | 200 |

| 110ZYT155 | 2230 | 3000 | 700 | 24 | 45 | 200 |