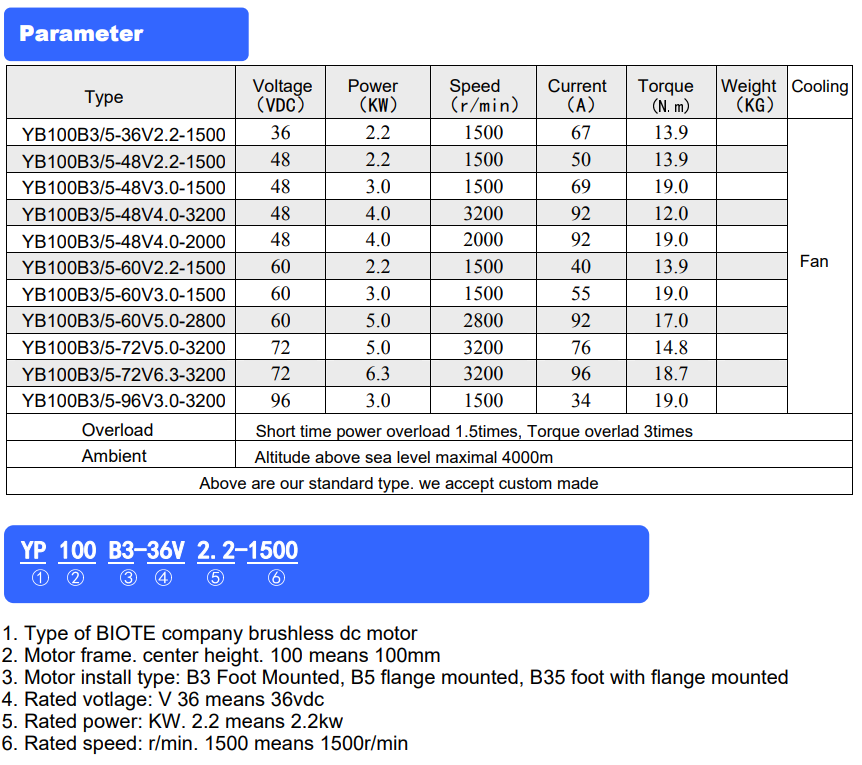

3kw 96v 1500rpm Brushless DC Motor

Features:

1. Motor type: Brushless DC motor

2 .Gearbox: Worm gearbox, reducer

3. Power: 3KW

4. Voltage: 96V

5. Speed: 1500rpm

6. Torque: 19.0N.m

7. Shaft dia: 28mm

8. Direction: CW /CCW

9. Addition: Manual brake

10. Typical application: Electric vehicles, Industrial automation, boat propulsion, industry drive, transport robot Power tools, Medical equipment, Cleanning machine, HVAC systems

11. Customized service: Motor's performance parameter, Shaft type, Wires and connectors

- Information

- Video

- Downloads

3kw 96v 1500rpm Brushless DC motor

Brushless motors have found practical application in hydraulic pump stations, offering several advantages over traditional motor systems. Here is an overview of the application of brushless motors in hydraulic pump stations:

Efficient Power Conversion: Brushless motors excel in efficiently converting electrical energy into mechanical power. By eliminating the need for brushes and commutators, these motors minimize energy losses and heat generation. The high efficiency of brushless motors translates to reduced power consumption in hydraulic pump stations, resulting in cost savings and improved overall system performance.

Precise Control and Speed Regulation: Brushless motors provide precise control over speed and torque, allowing for accurate regulation of hydraulic pump operations. By adjusting the motor's electronic commutation, the speed of the pump can be precisely controlled, enabling efficient fluid flow and pressure regulation. This level of control is crucial in hydraulic systems that require precise and responsive operation, such as industrial machinery and hydraulic power units.

Compact Design and Space Optimization: Brushless motors feature a compact and lightweight design, making them suitable for applications where space is limited, such as hydraulic pump stations. The absence of brushes allows for a more streamlined motor design, optimizing the use of available space in pump station installations. Compact brushless motors facilitate flexible integration into various system configurations and ensure efficient use of space.

Reduced Maintenance and Longer Lifespan: Brushless motors have a longer lifespan compared to brushed motors, as they do not have brushes that wear out over time. This results in reduced maintenance requirements and increased system reliability. Hydraulic pump stations equipped with brushless motors experience less downtime and require fewer maintenance interventions, improving overall operational efficiency.

High Power Density: Brushless motors offer high power density, meaning they can deliver a considerable amount of power in a relatively small size. This characteristic is advantageous in hydraulic pump stations, where space constraints may require compact motor solutions without compromising power output. The high power density of brushless motors allows for the efficient utilization of available space in pump station designs.

Enhanced System Performance and Flexibility: The use of brushless motors in hydraulic pump stations enhances system performance and flexibility. These motors provide smooth and precise operation, reducing vibration and noise levels. Moreover, brushless motors can be easily integrated into control systems, allowing for seamless communication and coordination between the motor and other components of the pump station.

Overall, brushless motors offer numerous benefits in hydraulic pump stations, including efficient power conversion, precise control, compact design, reduced maintenance, and enhanced system performance. Their advanced technology and reliability make them well-suited for a wide range of hydraulic applications, enabling optimized fluid flow, efficient energy usage, and improved productivity in various industries.

We also supply brushless dc motor with 12v 24v 48v. 72v.etc. if you need it. please contact us!

Higher Efficiency: Brushless motors achieve higher efficiency than brushed motors due to their design that eliminates the need for brushes, which reduces energy loss due to friction. This makes them ideal for applications where energy efficiency is critical.

Longer lifespan: Brushless motors have fewer moving parts, which results in less wear and tear, and thus a longer lifespan than brushed motors. This makes them ideal for applications where maintenance costs are a concern.

High torque density: Brushless motors can produce high torque at low speeds, which makes them ideal for applications that require high power and precise control.

Precise Control: Brushless motors provide precise control over speed, torque, and position, which makes them ideal for applications that require high accuracy and repeatability.

Low Noise: Brushless motors operate with lower noise levels than brushed motors, due to their design that eliminates the need for brushes and commutators.

Biote Brushless DC motor

Brushless DC motors are widely used for many industrial applications as they have many advantages:

•High efficiency and high torque in a small diameter

•Low starting voltage,low rotor intertial, low noise,long lifetime

•wide range of speed control and steady working state with less inaccuracy

•The size according Y2 motor to design. easy install

Widely used in automation equipment such as Copier ,printing machinery,Engraving machine,packing machine,grinting machine,robot,machine tool,Milling machine,Sewing machine,Engraving machine,Medical apparatus,ATM machine ect.

The brushless DC motor are accept custom. please contact us send the power. voltage. speed and so on.We can give best ieda

This type of brushless dc motor alsop have other frame size

YB80 series Brushless DC motor

YB90 series Brushless DC motor

........

YB32 series Brushless DC motor

the power from 0.5kw- 15KW. .

Perfect ventilation cooling

Low power, electric-saving and money-saving

Reduce construction cost of the investment and enhance economic efficiency

We can also supply the brushless dc motor controller

This is brushless dc motor controller